- 08

- Jan

BEST CARRIER TAPE SOLUTIONS

Are you looking forward to build plans or coming up with an idea to buy best embossed carrier tape/cover tape at lower prices than used carrier tape for your electrical compponents, like:IC, resistance, inductance, capacitance, connector, SMD LED, fuse, switch, relay, connector, oscillator, integrated SMD carrier, diode, triode and other SMT connector electronic components packaging with small business or industrial manufacturing in USA, UK, UAE, Canada, Australia, Russia, South Africa, China, Japan, India or other countries from Asia, Europe, North America, South America, Africa, and Oceania?

Review the new buying guide for ESD carrier tape /cover tape , carrier tape machine operators, beginners, carrier tape distributors, carrier belt factories, carrier band supplier, carrier tape retailer,wholesaler, engineer of carrier tape, carrier tape Technicians, and inspection of carrier band, we’ll offer you the best embossed carrier tape with expert customer carrier tape/upper cover tape service to meet your custom SMD packaging projects, ideas, and plans within your budget.

DEFINITION

What Is the carrier tape?

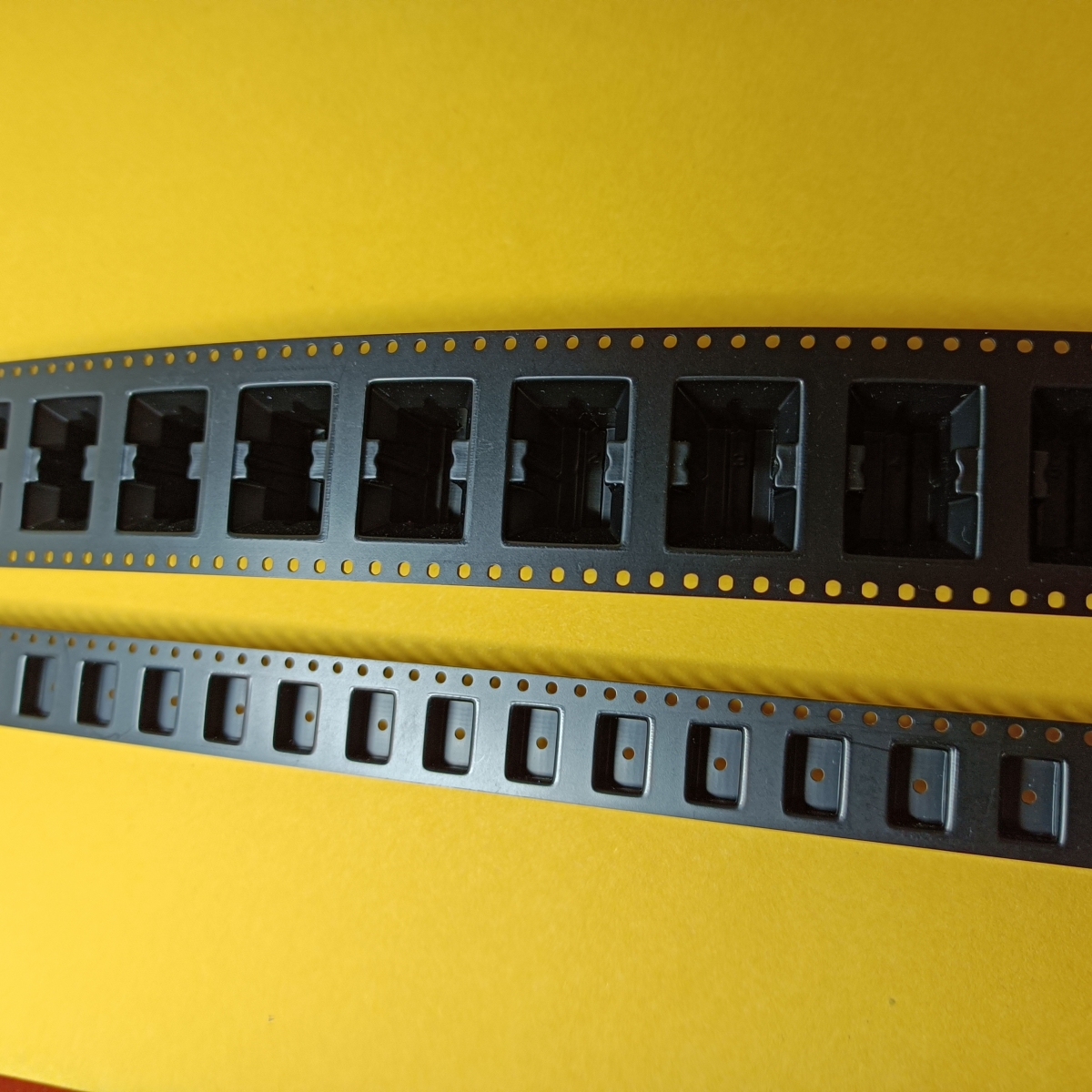

Carrier tape refers to a strip product used in the field of electronic packaging. It has a specific thickness, and holes (also known as pockets) for holding electronic components and positioning holes for index positioning are equally distributed in its length direction

During the mounting of electronic components, the cover tape is stripped, and the automatic mounting equipment takes out the components contained in the pocket in turn through the accurate positioning of the tape index hole, and pastes and installs them on the integrated circuit board (PCB).

PRINCIPLE

How about Carrier Tape Forming Machine?

- The flat plate type carrier tapeforming machine is suitable for belts above 12mm, especially those with Ko greater than 4mm; The forming stability of panel airborne belt is poor, and it is difficult to control P2 and F values, so it is difficult to make precision forming.

- The roller tapecarrier has a forming system composed of a female die and a male die. The precision of the male die can ensure the precision of belt carrier forming. The current equipment can reach ± 0.05mm, and the imported belt carrier forming machine can reach ± 0.03mm

Type of Carrier Tape

How Many Types of carrier tape?

By width:

According to the size of the electronic components carried by the package, the carrier tape is also divided into different widths. Common widths are 8mm, 12mm, 16mm, 24mm, 32mm, 44m, 56mm, etc.

With the development of the electronic market, chips tend to be smaller and smaller, and the carrier tape is also developing in the direction of precision. There is already a supply of carrier tape with a width of 4mm in the market.

By function:

In order to protect electronic components from electrostatic damage, some precision electronic components have clear requirements for the antistatic level of the carrier tape.

According to different antistatic levels, the carrier tape can be divided into three types: conductive type, antistatic type (electrostatic dissipation type) and insulating type.

By forming characteristics of the pocket:

Embossed carrier tape and punched carrier tape. Embossed carrier tape refers to a pocket with concave shape formed by stretching the local part of the carrier belt material through die embossing or blistering. This carrier tape can form pockets of different sizes according to specific needs to adapt to the size of electronic components; Stamping carrier band refers to forming penetrating or semi penetrating pockets through die punching. The thickness of electronic components that can be contained by this carrier tape is limited by the thickness of the carrier belt itself, and generally can only be used to package smaller components.

By carrier tape material:

The material of carrier tape mainly includes two categories: plastic (polymer) and paper. Embossed carrier tapes are mainly composed of plastic materials. The mainstream in the market are PC (polycarbonate), PS (polystyrene) and ABS (acrylonitrile butadiene styrene copolymer resin). In addition, there are also a small amount of carrier tapes prepared from pet, APET and other materials. The stamping carrier belt is mainly made of paper material or PE composite material.

By forming method of the carrier tape:

According to the forming mode of the pocket, it can be divided into two forming modes: intermittent (plate molding) and continuous (roller rotation). Compared with the batch forming method, the continuous forming method has better dimensional stability and higher dimensional accuracy. For the batch forming method, it is more suitable for preparing large pockets.

APPLICATIONS

What Are Carrier Tape/Cover Tape Used For?Carrier tape is mainly used in electronic component mounting industry. It is used together with the cover tape (upper sealing belt), carries and stores electronic components such as resistors, capacitors, transistors and diodes in the pocket of the carrier belt, and forms a closed package by sealing the cover belt above the carrier belt, so as to protect electronic components from pollution and damage during transportation. During the mounting of electronic components, the cover tape is stripped, and the automatic mounting equipment takes out the components contained in the pocket in turn through the accurate positioning of the tape index hole, and pastes and installs them on the integrated circuit board (PCB).

Most of the sheets used for the carrier belt are conductive or antistatic materials, which are produced by three-layer coextrusion. Due to the high requirements of the carrier tape, imported raw materials are usually used. The reason for using three-layer coextrusion is that two layers of the surface are made of conductive or antistatic materials, and the middle layer is made of ordinary plastic materials, which can meet the requirements of customers, It can also reduce the sheet cost with large radiance. Therefore, the hot and difficult point in the development of tape carrier is the coextrusion technology of tape carrier sheet, and the detection technology is receiving more attention.

Future development trend of plastic carrier tape technology

The production of plastic carrier tape will pay more attention to environmental protection and meet environmental requirements. Pollution-free green electronic product packaging materials will receive greater attention.

The technology of plastic carrier belt will be improved with the development of SMD technology, and high-speed vacuum forming technology will be more widely used.

SPECIFICATIONS TECHNICAL

All carrier tape and cover tape specifications are designed in accordance with international standards, and the supporting specifications of carrier and upper belt are as follows:

Carrier tape: 8mm 12mm 16mm 24mm 32mm 44mm 56mm 72mm 88mm 102mm

Cover tape: 5.4mm 9.3mm 13.3mm 21.3mm 25.5mm 37.5mm 49.5mm 65.5mm 81.5mm 101.5mm

BENEFITS GUIDE

Features

Carrier tape features:

① Not easy to deform, better component protection

② The carrier tape is stable in size and not easy to jam

③ The pocket size is accurate and suitable for loading small components

④ It is not affected by the outside world and can adapt to various storage and processing environments

⑤ It is not easy to break the belt, lengthen the packaging and reduce the downtime

⑥ Suitable for all kinds of packaging machines

⑦ Safety and environmental protection

Raw material characteristics of carrier tapes:

① Shrinkage (60C / 85% RH): < 0.1%

② Maximum service temperature: 125 ° C

③ Tensile strength: 63Mpa

④ Thermal deformation temperature: 135 ° C

Advantages

Superior conductivity, high strength, not easy to break, not easy to deform, stable size, anti-wear, long scratch length, customized, ion contamination resistant, high temperature baking, halogen-free and environment-friendly

Materials of the CarrierTape

The materials used to produce carrier tapes are mainly PC and PS;

PC material is one of engineering plastics. PC is the abbreviation of polycarbonate, and polycarbonate is polycarbonate in English, which is referred to as PC engineering plastics. As a material widely used in the world, PC has its own characteristics, advantages and disadvantages. PC is an amorphous thermoplastic resin with excellent comprehensive properties, with excellent electrical insulation, elongation, dimensional stability, chemical corrosion resistance, high strength, heat resistance and cold resistance; It also has the advantages of self extinguishing, flame retardant, non-toxic and colorable. You can see the shadow of PC plastic in every corner of your life. The characteristics of large-scale industrial production and easy processing also make its price extremely low. Its strength can meet all kinds of needs from mobile phones to bulletproof glass. The disadvantage is that it has insufficient hardness compared with metal, which makes its appearance easier to scratch, but its strength and toughness are very good. Whether it is heavy pressure or general wrestling, as long as you don’t try to hit it with a stone, it will live long enough.

PS English name polystyrene, chemical name polystyrene

Chemical and physical properties of polystyrene; Most commercial PS are transparent, amorphous materials. PS has very good geometric stability, thermal stability, optical transmission characteristics, electrical insulation characteristics and very small moisture absorption tendency. It can resist water and diluted inorganic acids, but can be corroded by strong oxidizing acids such as concentrated sulfuric acid, and can expand and deform in some organic solvents. The typical shrinkage is between 0.4 and 0.7%.

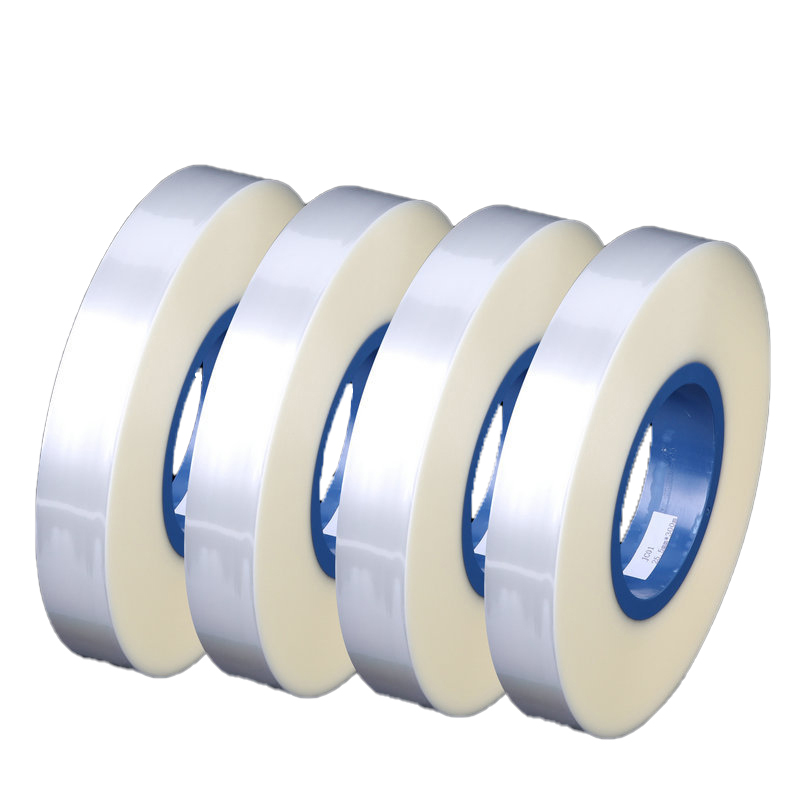

Form of Cover Tape

The cover tape in the tape carrying system has two ways: thermal and pressure-sensitive. The thermal cover tape has no viscosity at room temperature and has viscosity only after heating; Both sides of the pressure-sensitive cover tape have viscosity at room temperature. Just like the electrical insulating tape, it does not need to be heated. Compared with the thermal cover tape, the pressure-sensitive cover tape has four advantages:

- No heating, easy to use;

- The adhesion is very stable and not easy to degumm;

- There is no obvious difference between the effect of re bonding and the effect of initial bonding, so it is very convenient to replace components;

- The anti-static effect is better and can reach the electrostatic conductivity level

SMD Carrier Tape Standard

Range

This standard covers the packaging standard of SMD components.

brief introduction

The purpose of this standard is to provide the size and width standard of bearing belt for the use of automatic machine.

Applicable documents

Except for special purposes, the following documents form part of this standard

EIA-383 “preparation for shipment of electronic components”

EIA-541 “ESD sensitive element packaging material standard”

EIA-556 “EIA bar code standard for external shipping packaging”

EIA-583 “standard for packaging materials for moisture sensitive components”

EIA-624 “packaging bar code standard for non retail products”

About the Reel Taping

Reel: made of polystyrene (PS) material. It can consist of one to three parts. Its colors are different (blue, black, white or transparent) and can usually be recycled (most suppliers participate in the environmental responsibility regeneration program). The reel size is specified in EIA-481 standard

The plastic materials commonly used in the lower tape of packaging include the following: polyolefin (HDPE, PP), polystyrenes (PS, imps, ABS), polyvinyl chorides (PVC), polyesters (PET, APET, PETG) and polycarbonates (PC). The above materials have different physical properties due to different materials, including toughness, impact resistance, strength, light transmittance and dimensional stability. The packing belt made of any material must have its own advantages and disadvantages. Therefore, before deciding which lower tape material to use, we must first understand its characteristics and give appropriate packaging in order to operate smoothly on the pick & place machine.

Antistatic of the Carrier Tape

Surface impedance value at:

1011↑ insulation

109(without)∽1011(with)Antistatic

106(without)∽10(with) electrostatic dissipation

10(with)↓ conductive

BUYING GUIDE

How To Buy The Carrier Tape ?

There are many varieties of carrier tape in the world, and there are also many brands and manufacturers. This phenomenon has advantages and disadvantages for buyers. The advantage is that consumers have more choices, and buy more cost-effective carrier tapes. The bad thing is that after seeing more, they have no choice and don’t know which one is the best to buy.

As the saying goes, cheap carrier tape are not good tapes, and good carrier tapes are not cheap. So, what things should be considered when buying carrier tape? Meet Your Requirements Let’s not think that a carrier tape can do all the work. Why do manufacturers divide carrier tape into so many types, in order to be able to pack different electrical components professionally. If you buy carrier tape , or buy a certain cover tape, it will not only waste a lot of money but also have a bad effect.

So how to better choose a good carrier supplier?

First, select some suppliers of corresponding products through Google platform search or other B2B platforms;

Then, analyze and verify these suppliers. In this process, we should carefully see whether they are professional exporters, manufacturers or factories in the belt carrying industry.

For grocery exporters, we first exclude them, because the tape carrying is a kind of products with scientific and technological content, and non professional suppliers or business personnel may lead to more time waste;

Next, we need to see the matching degree between suppliers and their own companies. For example, if you are a small and medium-sized company that has just started, it is not suitable to find well-known manufacturers in the industry.

At first, when your number is small, it is difficult to get better cooperation, delivery date and various requirements.

At this time, the matching suppliers should be small and medium-sized companies or factories.

If you are a purchaser of a well-known company, you should exclude small factories or companies with insufficient supply capacity at this time. Only in this way can you better find a tape manufacturer suitable for your company. When this step is completed, we may still have 2-3 suppliers to be selected; This is the time to test the business ability of the carrier supplier and other cooperation ability; The quotation you ask for, the reply of each salesman will be different; Simply, I will give you a quotation, reply and urge you to confirm the information.

If I purchase such a factory, I may just keep it for standby; There are also many conditions that may be set, such as requiring a certain starting order quantity, such as asking how many orders are first. For example, they will tell you that they don’t cooperate with small companies, what kind of orders they don’t take, and they can’t look at factories without cooperation. Such factories will have very poor cooperation in the later stage, so they should pass as soon as possible. There is another kind of business personnel. They will not quote at the first time. They may send you an email to introduce their factory, and then ask you some questions that may need attention in the quotation. After all the questions he needs to know are clear, a detailed but not complicated quotation is presented to you. At first glance, such business personnel have very high comprehensive quality, The business ability is also very strong. If you cooperate with such a factory / company, you will be very comfortable. In case of problems, he can also provide you with a variety of solutions. This is the preferred partner!

Having said so much, in fact, we sincerely hope that you can be more smooth when choosing a cooperative company, so that you can have a good experience in the process of carrier tape purchase, buy qualified products and ensure the smooth delivery of production