- 10

- Jan

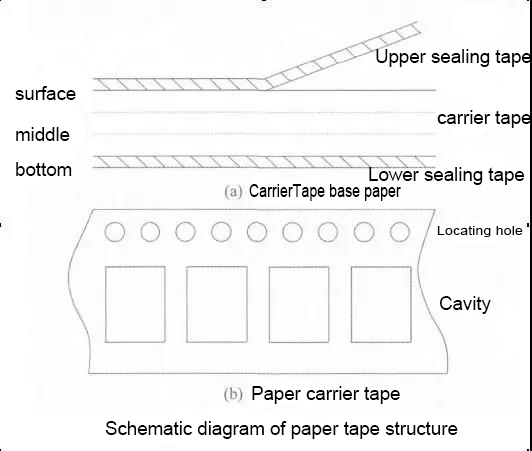

Paper carrier tape base paper structure

The paper carrier tape base paper needs to have the following characteristics: small thickness fluctuation, repeated winding without layering, high surface strength and certain hot-melt adhesion, water and moisture resistance, strict control of chemical composition to ensure that it does not corrode electronic components, and the paper surface is clean and free of stains and impurities.

The paper tape carrier paper usually consists of three layers (or more), i.e. the surface layer, the middle layer and the bottom layer. The tape carrier is evenly distributed with positioning holes and cavities. The cavities are used to hold electronic components, and the electronic components are sealed inside the tape carrier through upper and lower sealing tapes

The lower sealing tape can prevent the leakage of electronic components from the bottom. The upper sealing tape is often coated with hot-melt adhesive to seal the upper part of the pocket. Electronic components determine the shape and size of the cavity. Usually, the cavity hole is a through hole, but also a stepped hole and a blind hole. The machining accuracy of the hole is required to be high. It is necessary to strictly control the powder loss in the hole cavity and ensure sufficient machining accuracy to avoid mechanical vibration damaging electronic components in access and transportation projects