- 18

- Jan

What is the carrier tape,cover tape,reel?

1、 Three in one use of carrier tape, upper cover tape and rubber reel

Detailed description of carrier tape

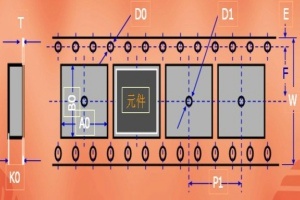

2、 Size of carrier tape (1)

Detailed description of carrier tape

W: carrier tape width

Po: center distance of guide hole

P2: horizontal distance between the center hole of forming groove and the center of side hole

P1: distance between center holes of two adjacent forming grooves

E: Vertical distance between guide hole center and belt edge

F: Vertical distance between the center of the guide hole and the center of the forming groove

Do: guide hole diameter

D1: diameter of circular hole in the center of forming groove

T: Strip thickness

A0: transverse width of forming groove

Bo: longitudinal width of forming groove

Ko: vertical distance between forming groove surface and groove bottom surface

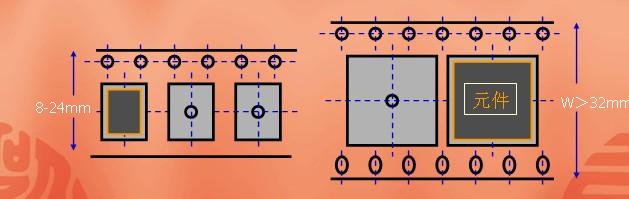

Size of carrier tape (2)

The positioning holes of V 8-24 bandwidth are only on one side, and the positioning holes of W > 32mm are on both sides,

The accuracy varies with the width of the carrier belt. The wider the carrier tape, the greater the allowable tolerance

Detailed description of carrier belt

3、 Requirements for use

1. Sealing and stripping requirements (20g-80g) are as follows:

8mm CARRIER TAPE: 20g-80g

12-56mm CARRIER TAPE: 20g-130g

>72mm CARRIER TAPE: 20g-150g

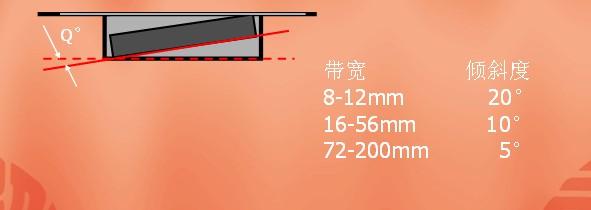

Detailed description of carrier tape

The allowable rotational displacement (1) of the device is shown in the following figure

Detailed description of carrier tape

3、 Function of carrier tape

1. Easy to carry 2. Guaranteed efficiency 3. Product model 4. Quantity and length 5. Electrical protection 6. Bearing and conveying 7. Packaging function

4、 Type of carrier tape

(1) Narrow band: 8mm and 12mm

(2) Broadband: 16mm, 24mm, 32mm, 44mm, 56mm, 72mm

Note: the length of carrier tape depends on the customer’s packaging quantity requirements

(3) Narrow band features: made by circular turbine, raw material PC PS, fixed mold, large output, long meters, more precision and higher requirements. (bandwidths of 8mm and 12mm are conventionally referred to as narrow band. The materials commonly used for this kind of carrier band are PC, PE and PS)

(4) Broadband features: tablet machine manufacturing, PS raw materials, changeable molds, small output, wide variety, complex molding, and short meters. (bandwidths of 16mm, 24mm, 32mm, 44mm, 56mm, 72mm, 88mm, etc. are commonly referred to as broadband. The materials commonly used for such belts include PE, PS, ABS and PVC)

5: With introduction

(1) The full name is “cover tape on electronic packaging”, which is abbreviated as “cover tape” and “cover tape” in English.

The categories are: according to the sealing conditions, it can be divided into heat sealing upper belt and self-adhesive upper belt; According to the electrical properties of materials, they can be divided into Anti electrical type and non electrical type.

Bandwidth: 5.3mm, 9.3mm, 13.5mm, 21.5mm, 25.5mm, 37.5mm, 49.5mm, 65.5mm and other specifications,

Pet is generally used as the basic material;

Detailed description of carrier belt

(2) Upper cover tape: the upper belt of heat sealing type can be bonded only after heating in the sealing equipment. The length of such upper belt is generally 300m / R and 480m / R; The appearance is transparent and milky white;

The self-adhesive upper cover tape does not need to be heated in the sealing equipment. Because the material has pressure sensitive material, it can be sealed automatically by adding pressure during sealing.

The length of such upper belt is generally only 200m / R. The appearance is transparent and brown. In terms of electrical properties, there are only two types: anti electrical type and non electrical type.

The surface resistance of the anti electric type is 107-11 Ω / □.

The surface resistance of non electrical type is more than 1012 Ω / □.

(3) Upper band property: ordinary type, electrical resistance, color: milky white and transparent color, length: 300m / R and 480m / R

Due to the different formulas of different manufacturers, the upper belt has its own matching. The upper belt of any manufacturer cannot be matched with the carrier belt of another company. The sealing of all upper and lower belts must be tested and approved before they can be matched and supplied to customers. All materials used in the upper belt must comply with the EU environmental protection directive RoHS for electronic and gas products, and the specific relevant element standards are the same as those of the carrier belt.

6、 Reel

The full name of reel is “electronic packaging reel”, which is referred to as reel, rubber disc and wheel disc. English: “reel”. This is a reel in the customary sense. In a broad sense, there are also plastic reels and paper reels. Generally, plastic reels are purchased and sold independently, and paper reels are attached.

(1) Reel category: it can be divided into 7 inches, 13 inches and 15 inches according to the diameter of the reel. Narrow band generally uses 7-inch rubber disc. Generally, 13 inch or 15 inch rubber discs are used for broadband. PS is generally used as the material;

The thickness includes 8mm, 12mm, 16mm, 24mm, 32mm, 44mm, 56mm, 72mm, 88mm, etc.

Its thickness is mainly determined by the carrier belt used by customers.

Note: (tape width = reel thickness)

Detailed description of carrier tape

(2) The reel can be divided into conductive materials, anti electric materials and non electric materials according to the electrical properties of the materials used. The conductive rubber disc is generally black in appearance, and the surface resistance value is 104-6 Ω / □;

The appearance of anti electric rubber disc is black, blue and white. The surface resistance value is 107-11 Ω / □; Because it is made by soaking in electrostatic solution, the surface is slightly wet and the shelf life is only six months.

Non electric rubber reel, no static liquid. Appearance: blue, white. The surface resistance value is 1012 Ω / □ or more; Due to different purposes, its axis is different. Generally, the axis of IC rubber disc is smaller and others are larger.

(3) Material category: PS material; PC materials; ABS material; Single layer material; Three layers of material.

Material properties: PS transparent material; PS conductive material; PC transparent material; PC conductive material; ABS conductive material; Single layer material; Three layer material

(4) Tape carrying materials: according to the electrical properties of materials, they can be divided into conductive materials, anti electric materials and non electric materials.

Ø conductive material, black in appearance, opaque, with surface resistance value of 104-6 Ω / □;

Ø electrical resistant material, black in appearance, opaque, with surface resistance value of 107-11 Ω / □;

Ø non electrical material, colorless and transparent in appearance, with a surface resistance of more than 1012 Ω / □.

PC material has good toughness and strength, followed by PE (ABS) and PS.