- 04

- Nov

How does known the different Carrier tape forming Machine

Usually , we meet some customers didn’t actually know what kind of carrier tape forming machine can fit their requirement; some of them didn’t even understand what’s the difference from various manufacturers.

This kind of information gap cause the customers frequently don`t know how to find the right carrier tape supplier.

The applicable tape width of the rotary machine can be up to 24 mm, and the applicable tape width of the embossed machine can be up to 88 mm. They have the overlap market when the carrier tape width about 8-24 mm.

We sincerely recommend that you should get the detail understand equipment working before order.

There are significant differences in performance, quality, and design concepts of the carrier tape forming machine from various manufacturers.

So, this article proposes three major factors, hope this can help you make right choice.

1. Machine Type

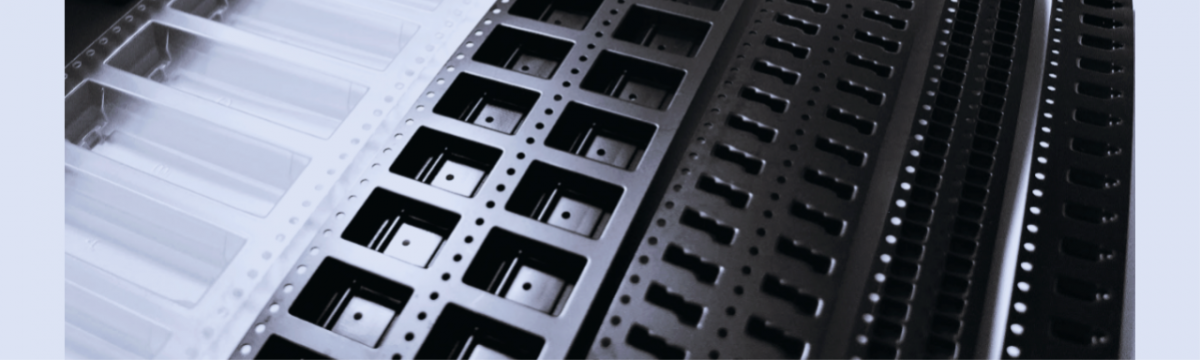

The carrier tape forming machine can be roughly divided into embossed machine and rotary machine, their respective extension models. They have different advantages and disadvantages according to the different design concepts of various manufacturers.

a) Embossed Carrier Tape Forming Machine

The embossed machine is using the clamp in tracks to transfer the carrier tape, the main forming method is Heat Air-box or Metal Stamping; then divided into cam type and cylinder type according to the different forming operations.

b) Rotary Carrier Tape Forming Machine

The rotary machine is using the multiple axle rolling to transfer the carrier tape, the forming method is Heat Air-gun; then extend to the Carrier Tape Extrusion and Forming Machine according to add the extrusion machine or not.

c) Total comparison

Generally speaking, due to the different forming methods, the carrier tape from embossed machine was almost no curl, the carrier tape from rotary machine was definitely curled.

Following, we try to compare the advantages and disadvantages of different models in the carrier tape manufacturing process.

2. Design Concepts

From the standpoint of equipment manufacturers, the design concept of an equipment is the most important thing.

Without a good design concept as the foundation, not only the carrier tape is hard to forming and the dimension is difficult to adjust; sometimes the users even have to modify the machine to adapt to the specific carrier tape production. You really should not putting the cart before the horse.

a) System integration

One is make the machinery subordinate to electrical control, and integrate all data on a single system for control; Another one is not only has a simple operation interface and precise control, but also help the optimization and upgrade of overall functions in the future ( Carrier Tape Forming Machine).

Now, many manufacturers are outsource the electrical control, programming, and partial assembly under cost consideration; it may not only cause the quality of equipment inconsistent, but also make the equipment maintenance and system upgrades very difficult.

b) Adjustability

Some approach is to design more adjustable functions on the equipment, so the customers can use one model to meet most of their need; you can make the W = 8-104 mm, Ko = 1-30 mm carrier tape on the same carrier tape forming machine .

Because we really care about the adjustability of the equipment,

c) Modularization

All the equipment used the modular design, most of the mechanism can be dismantled by the attached tools.