- 05

- Nov

How Carrier Tape packaging of electronic components

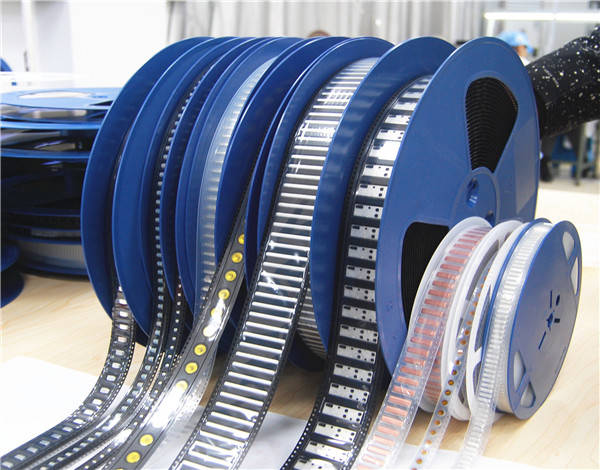

Tape packaging of electronic components

Tape packaging of electronic components

That is, the electronic components are placed in the carrier tape and packaged through the cover tape.

After the packaging is qualified, they are packaged and stored through the carrier tape reel. When packaging the carrier tape, the ratio of chip area to packaging area is mainly considered. In order to improve the packaging efficiency, the ratio should be as close as possible to 1:1.

The pins should be as short as possible to reduce delay, and the distance between pins should be as far as possible to ensure no interference and improve performance. Based on the requirements of heat dissipation, the thinner the package, the better. Another task of carrier tape packaging is tensile test to test whether the carrier tape packaging is qualified.

The carrier tape cover tape stripping tester is a testing machine specially developed and designed for carrier tape / cover tape stripping force test. The total pulling force of the cover tape used by carriers of any type and material. If the carrier is 8mm, it shall be 0.1N to 1.0N (calibrated scale value of 10 to 100g); For carriers 12 mm to 56 mm wide, it shall be 0.1N ~ 1.3n (10 to 130 g calibrated scale value); 0.1N ` 1.5n for carriers 72 mm and wider.

Pull out refers to separating the covering belt of the whole width from the carrier or stripping the central part of the covering belt from the carrier so that the elements can be taken out of the grid. The direction of the tensile force shall be opposite to the running direction of the carrier, and the stretched covering belt has a clamping degree of 165 ~ 180 with the top of the carrier. In the tear force test, the covering tape shall be stretched at a speed of 300 + / – 10 mm / min relative to the carrier, which will cause the sealing of the covering tape / carrier to separate at a rate of 150 mm / min.