- 05

- Nov

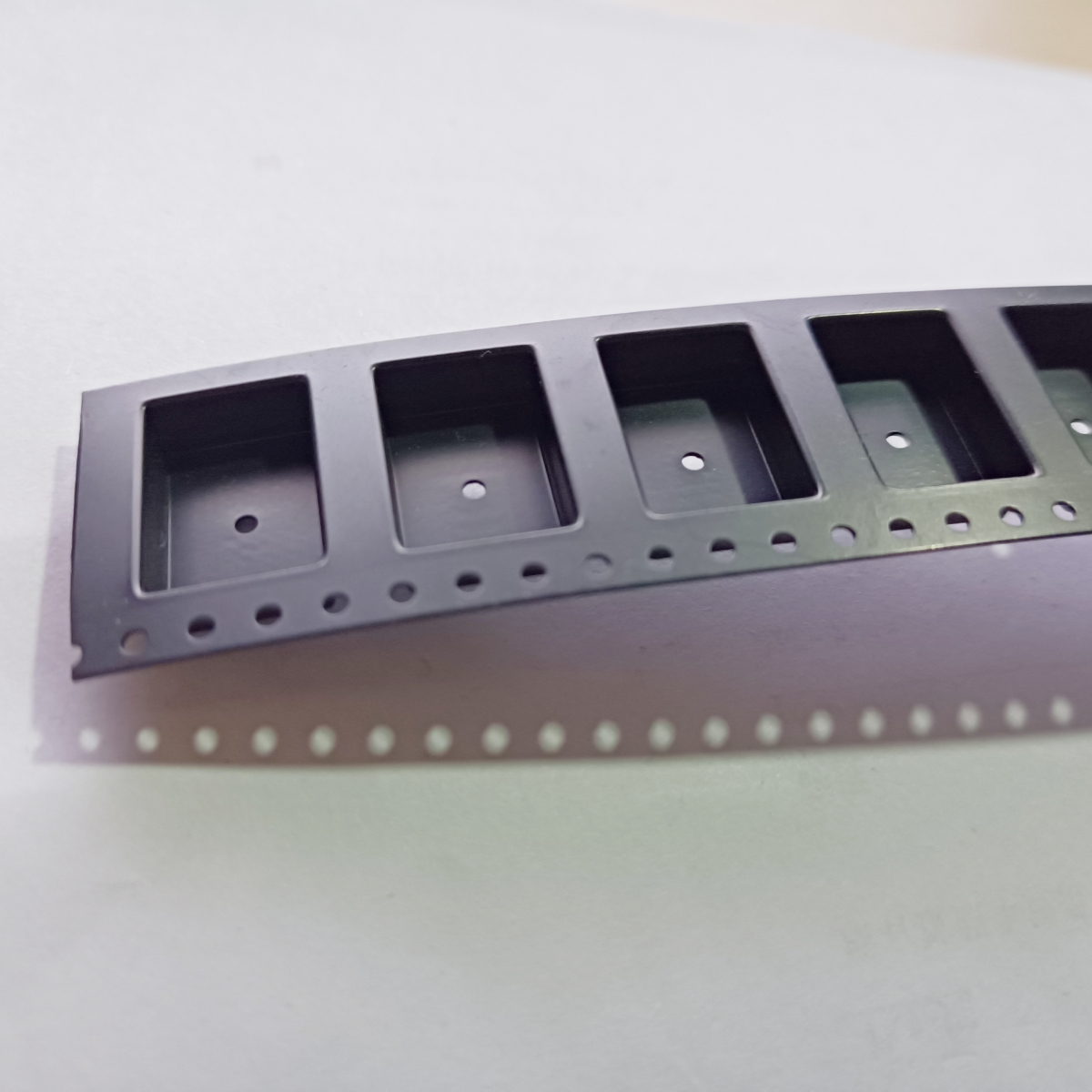

Why is the E value of PS conductive carrier tape too small

In the manufacturing and adjustment of carrier tape, it is a common problem that the E value is too small:

1、 The position of punching machine die is not mastered in time, which is the most likely poor situation in belt manufacturing. If the punching die shifts, it means that the stamping die and the slide rail are not on a parallel line, which is very easy to cause the E value of the carrier belt to be too small; If the punching die is too far back and does not stick to the punching die, the punching needle enters next to the carrier tape, which is also very easy to cause the E value of the carrier tape to be too small. Therefore, the position of the punching die should be mastered in time.

2、 Under the condition that the load on the die head is not worn through the groove, the change of the die head or the change of the fixed plate of the punching needle can not be adjusted in the processing technology, resulting in the small e value.

3、 The pressing head crushes the edge of the raw material, resulting in the bulge of the raw material edge. When the raw material enters the stamping die, the bulge will make the raw material unable to approach the stamping die, resulting in the small e value of the carrier belt.

4、 Safety hazards such as belt shrinkage or raw material bending may also lead to small belt e value.

5、 If waste enters the guide groove of the stamping die and causes the guide groove of the stamping die to be bruised, it will also easily cause the E value of the carrier tape to be too small.