- 06

- Nov

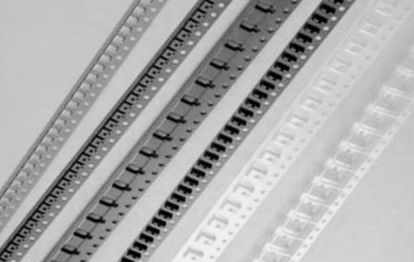

Why are there bubbles in PET Carrier tape production?

We specialize in the production and processing of electronic IC carrier tapes. Recently, there are many bubble problems in PET material production, which always occur intermittently and repeatedly. Based on the production conditions, the upper and lower heating mold temperatures of the machine are 185 degrees. Please know why?

PET is a kind of crystalline polymer material.

As a kind of transparent plastic, due to the high light transmittance, the surface quality of plastic products must be strict, and there must be no defects such as spots, pores, whitening, fog, discoloration, black spots and poor gloss. Therefore, great attention and strict requirements are paid to in the production process.

Secondly, due to the high melting point and poor fluidity, the probability of adverse phenomena is relatively high, We must pay great attention to all kinds of work. In the overall processing process, strict and even special requirements are put forward for raw materials, equipment, molds and even products.

Therefore, the preparation and drying of raw materials may affect the transparency of products due to any impurities in plastics. Therefore, in the process of storage, transportation and feeding, attention must be paid to sealing to ensure that the raw materials are clean, especially the raw materials contain water. Heating will cause the deterioration of the raw materials, so it must be dried. The input air in the drying process must be filtered and dehumidified to ensure that the raw materials will not be polluted.

If the raw material contains water, bubbles will appear in the product, which will seriously affect the color of the product and even brittle.

Another possible bubble is affected by impurities. Due to its high melting point, the requirements for production temperature are also very strict. If the temperature you use does not reach the melting point, it will lead to poor plasticization of raw materials. Whether there is plasticization or not, and even the raw material sticks to the barrel wall or connecting port. During production, there will be bubbles if there is no plasticization due to extrusion and the raw material is extruded a little bit.

Because there are many kinds of PET, including high and low temperature, high viscosity and low viscosity, the temperature used to produce different raw materials is also different. For what you put forward, you should first understand what brand of raw materials you use. In view of your production process, we can analyze the complete reason.