- 10

- Nov

What is the contribution of carrier tape automation to the market

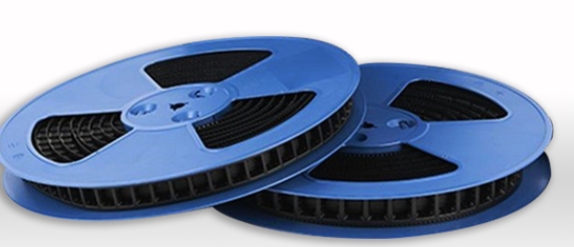

Since the emergence of the carrier tape system, it is mainly developed and designed on the micro carrier tape, so it has made good achievements in the small carrier belt,

Nowadays, with the continuous progress of society, in an efficiency oriented society, automatic production has been realized, which greatly reduces labor costs and improves efficiency,

As a pocket for material transfer, the carrier tape is continuously sent to the system of the automatic production workshop from production molding to packaging, so as to ensure that products can quickly enter the market from the production line, which is the contribution of automation to the market.

We should find out the problems in the tape production process in time. In the production process, the retraction and arrogance of tape packaging products at different temperatures are different.

Therefore, the environmental application is different. The packaging carrier tape of the same material has different sealing characteristics. Under the same belt packaging machine and the same sealing conditions,

PVC is more viscous than PS, and PS material can obtain higher viscosity than PC material, because each polymer has different surface energy. If you want to get the same viscosity, you need different temperatures to cooperate with each other.