- 10

- Nov

With the improvement of the utilization rate of electronic products, the global semiconductor packaging market is growing

With the improvement of the utilization rate of consumer electronic products, it is more and more used in the fields of Internet of things, artificial intelligence (AI), consumer electronics, robotics, telecommunications, automobile and so on, and the global semiconductor packaging market is growing.

In the surface mount (SMT) process, the packaging specification and packaging method of electronic components are very key, and directly affect the efficiency and quality of assembly production.

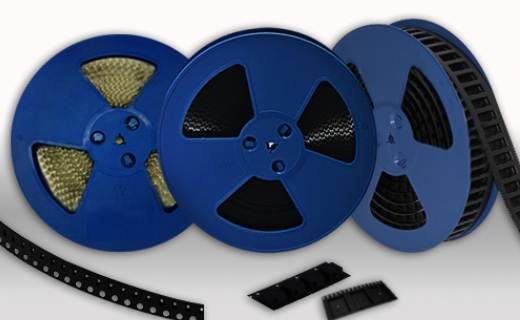

Different chip components have different packaging specifications to meet customer requirements, so as to turn the scheme into a product. In packaging, testing and OEM, SMD components have one of the common packaging forms, that is, tape packaging. Tape packaging is used for mass-produced electronic components.

Tape packaging is a packaging form with the most extensive application, the longest time, strong adaptability and high efficiency, and has been standardized. In SMT and component production lines, electronic component products with packaging can be found everywhere in the era of automation.

In the semiconductor chip packaging type, one side of the carrier belt is provided with a positioning hole, which is used to guide the carrier belt forward and position when the SMD components are picked up by the mounter.

According to the distinction of materials, tape packaging mainly includes paper tape and plastic

1. Paper tape is mainly used for packaging chip capacitors, chip resistors, cylindrical chip sot transistors, diodes, etc., with a bandwidth of 8mm. This kind of packing is usually coiled on a plastic frame.

2.2. Plastic carrier tape is used to pack various chip leadless components, composite components, special-shaped components, transistors, and chip components with few leads such as Sot, SOP and small-size QFP.

Packaging form is closely related to the shape and packaging specification of SMT components, which is an important factor affecting the production efficiency of SMT and SMD.

In the packaging and testing of components, it is necessary to grasp the development trend of electronic components and electronic manufacturing, select appropriate packaging methods of SMD chip components, complete efficient packaging and testing, and improve the quality of products.