- 11

- Nov

The main reasons for poor winding of general carrier tape are:

1. After production, the carrier tape is too loose or too tight

2. When the carrier belt was placed on the packaging machine table, the machine was not strengthened and fixed, resulting in an increase in the vibration amplitude of the carrier belt during the operation of the machine

3. Incorrect placement method when packaging the machine on the carrier belt

In order to solve the problem of bad winding of the carrier belt during installation, we need to do the following:

1. After production, the carrier tape shall be wound to the appropriate tightness, so as to have better operation when packaging the machine

2. When placing the carrier belt on the packaging machine table, the machine needs to determine whether it is strengthened and fixed to reduce the range of carrier belt vibration during the operation of the machine

3. When packaging the machine on the carrier belt, it can not be placed on a plane. The correct method should be to place the carrier belt upright

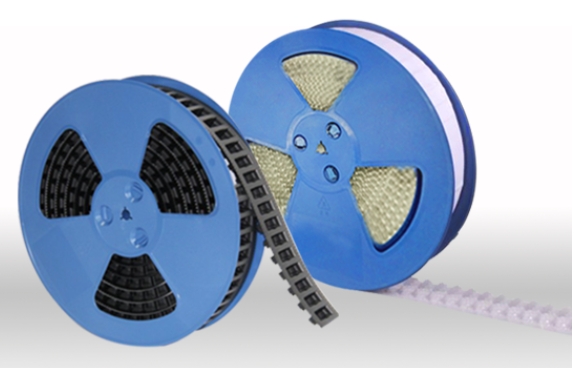

With the gradual development of electronic parts towards miniaturization, traditional packaging technology can not better meet the packaging of most electronic parts

Therefore, a new tape packaging technology for electronic parts has emerged. The load-bearing coil packaging technology can not only meet the packaging needs of most electronic parts

Moreover, compared with blister, load-bearing tape has more advantages and reduces labor cost. Load-bearing tape has become the main way of packaging in the electronic industry.