- 11

- Nov

With the development of SMD tape packaging industry and the progress of science and technology, various industries have increasingly exquisite requirements for packaging products

In order to be based on the highly competitive market economy, constantly develop new packaging materials and new products to improve quality management, manufacturers with a complete range of products.

From packaging to packaging, electronic parts have been sent to the feeding system of the automatic production workshop, which is responsible for correctly installing each part to ensure that the product can quickly enter the industry from the production line

SMD carrier tape acts as a carrier, which makes the whole messy parts orderly and placed together, making it easier for the manipulator to identify

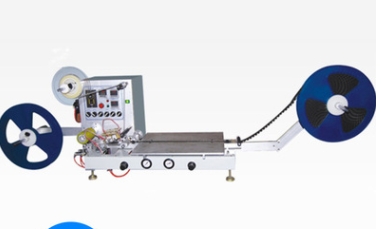

SMD module semi-automatic tape braiding and packaging machine. Suitable for batch SMD module packaging; It is convenient and fast to replace material belts with different widths and specifications. SMD carrier plays such a role.

Automation technology can greatly save labor costs and improve the competitiveness of products in the industry. The fineness of SMD carrier is higher.

From production molding to timely skill upgrading, SMD carrier belt is a pocket for material delivery. Now most enterprises complete automatic production

SMD carrier belt is the carrier of fine parts such as electronic components and hardware, which is the contribution of automation to the industry.