- 12

- Nov

What is the reasons for carrier tape skipping

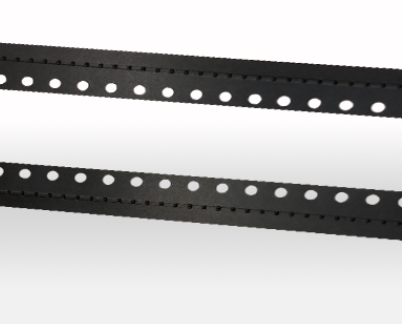

There are two reasons for tape skipping : one is that the tape jumps before loading the components, and the other is that the components jump after tape weaving.

The skip is mainly due to the mismatch between the size of the carrier belt and the component, the size of A0 and K0 is too large, which has little to do with B0, or the hardness of the material does not meet the standard

Therefore, it is easy to deform, affect the size, and it is difficult to control when braiding, resulting in material jumping, which can only change the size of the carrier belt or the hardness of the material.

In the latter case, K0 is too deep. As long as the die depth is changed to shallow, but at the same time, the more key and important factor can not be ignored is the use of inappropriate cover tape.

When sealing electronic components, especially very micro components, the cover belt must be close to the carrier tape after sealing. If it cannot be close, there is a gap between the carrier tape and the cover tape,

It will affect K0, and the electronic components are easy to cause overturning, that is, material jumping. Therefore, in order to improve this situation, in addition to the appropriate K0 of the mold, it is also necessary to select the appropriate cover tape.