- 06

- Dec

What is about the details standard of the carrier tape

.1 the carrier tape, upper cover tape, reel and packaged elements must meet the requirements specified in the chart herein—standard of the carrier tape

4.2 the interrogation of documents and quotations shall include the following information:

A: Indicate the name and number of the referenced standard;

B: Packaging quality requirements, including the maximum packaging quantity of parts;

C: Marking requirements for packaging box and reel (including bar code) and reel size;

D: Transportation conditions, storage conditions and storage time.—standard of the carrier tape

4.3 for the forming groove depth T2 and the forming groove spacing P1 of the loadable belt, the following applicable ranges must be considered. (see Figure 1 and Figure 2)

A: For 16mm and 24mm wide bearing belt, if T2 exceeds 6.5mm, it may not pass through the belt conveyor.

B: For 32mm, 44mm and 56mm wide bearing belt, if T2 exceeds 10.1mm, it may not pass through the belt conveyor.

C: For 24mm wide bearing belt, if P0 is less than 12mm, it may be mispositioned in the belt conveyor.

D: For 32mm wide bearing belt, if P is less than 16mm and 44mm wide, P is less than 24mm and 56 wide, and P is less than 40mm, it may be mispositioned in the feeder.

4.4 the possibility of parts falling out of the bearing forming groove shall be avoided after the upper belt is pulled away. Still keep it in its original position so that the machine can access it automatically.—standard of the carrier tape

4.5 the upper belt shall not cover the edge of the bearing belt or cover any chain perforations.

4.6 the bearing belts wrapped on the winding belt shall not be stuck together.

4.7 the packaging materials and packaging process shall not damage the mechanical and electrical characteristics of the parts, or leave any marks on the parts. For the intermediate process or final packaging standard, please refer to eia-383 “preparation for transportation of electronic components”; Eia-541 “ESD sensitive element packaging material standard”; Eia-583 “standards for moisture sensitive components” EIA, 624 “packaging bar code standards for non retail products”.—standard of the carrier tape

4.8 during the packaged storage process, the bearing belt shall not cause any damage to the parts, including unclean object pollution, transfer to the connector of the parts, or poor welding of the connector, damage to the characteristics of the parts, or even failure due to chemical reaction due to the release of moisture, and the covering belt shall not fall off, resulting in the position offset of the parts.

4.9 if the forming groove is cut from the place below K0 / 2 depth, the parts should be taken out smoothly. At the same time, this action should not affect the original packaging function of two or three adjacent forming grooves.

4.10 the upper belt shall have a total tensile strength of 0.1n-1.3n (10g-130g). The pulling direction must be the opposite direction of the feeding of the bearing belt, and it is at an included angle of 165-180 degrees relative to the surface of the bearing belt. The pulling speed is set at 300 ± 10mm / min

4.11 the placement direction of multi pin parts must follow the following standards, and shall be selected according to the following priority according to the applicable conditions. Note: these standards were previously published as EIA guideline 783.—standard of the carrier tape

A: In traditional packaging, only the parts with tin pins on the bottom (such as PICC, SOIC, SOJ, BGA, etc.) should be packaged. The pins should face the bottom of the forming groove, and the pins should be placed in the direction of the covering tape for the unpacked wafer.

B: The following rules apply whether the contact is up or down. Here, the contact is defined as the electronic connection between the circuit board and the parts, which may be described as pin, ball, contact surface, connector and No. 1 contact of the parts as the positioning point in the placement direction.

C: If the No. 1 contact of the part cannot be identified, or the contact is in the center of the part, the location point of the part shall be the identification point defined on the part.

D: The longest axis of the part (the long side of the part) should be perpendicular to the bearing bandwidth

E: On the part, the side where the first contact is located should be placed towards the chain perforation

F: If the above two rules still cannot define the placement direction, the contact shall be placed in the direction of the first quadrant shown in the right figure.

4.12 the reel (as shown in Figure 9) shall have obvious and permanent recycling marks.

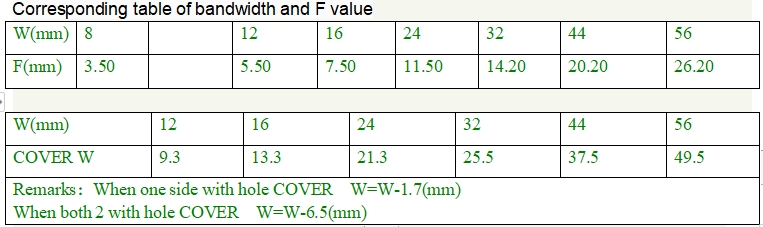

Corresponding table of bandwidth and F value—-standard of the carrier tape

carrier tape

carrier tape specification

carrier tape calculator

carrier tape supplier

carrier tape thailand

carrier tape drawing

carrier tape market

kostat carrier tape

carrier tape pitch

carrier tape width

jedec carrier tape

rothe carrier tape

0402 carrier tape

carrier tape burr

carrier tape hole

vtek carrier tape

8mm carrier tape

led carrier tape

ox3 carrier tape

carrier tape manufacturers usa

carrier tape forming process

carrier tape eia standard

carrier tape in spanish

plate carrier name tape

carrier tape and reel

3m carrier tape 3000

carrier tape que es

carrier tape là gì

carrier tape reel

carrier tape advantek

carrier tape splicing

blister carrier tape

carrier tape camber

jiemei carrier tape

carrier tape paper

keaco carrier tape

nitro carrier tape

carrier tape tray

carrier tape wiki

carrier tape hs

carrier tape manufacturing process

carrier tape surface resistivity

carrier tape forming machine

carrier tape design rule

carrier tape en espa?ol

carrier tape material

carrier tape forming machine suppliers

carrier tape manufacturer in malaysia

carrier tape semiconductor

carrier tape manufacturer

carrier tape design

tape handle carrier

carrier tape price

wafer carrier tape

carrier for tape

npi carrier tape

carrier tape a

embossed carrier tape thailand

carrier tape hs code

carrier tape manufacturer in philippines

carrier tape peel force tester

carrier tape distributors

carrier accounting tape

carrier tape production

carrier tape malaysia

embossed carrier tape

tekpak carrier tape

carrier film tape

carrier tape spec

non carrier tape

taiwan carrier tape enterprise co. ltd

carrier tape cover tape

carrier tape 3m

carrier tape manufacturers in india

carrier tape deutsch

carrier tape splicer

tape carrier package

carrier tape means

embossed carrier tape manufacturer

carrier tape length calculation

carrier tape suppliers in india

3m carrier tape and reel

carrier tape standard

carrier tape fit analysis

tape carrier package wiki

carrier tape tariff code

carrier tape what is

embossed carrier tape forming machine

3m carrier tape data sheet

carrier tape machine

3m carrier tape distributors

carrier tape supplier penang

empty carrier tape reels

carrier tape hs code singapore

carrier tape and cover tape

carrier tape dimensions

carrier tape supplier in the philippines

advantage carrier tape

eia carrier tape

itw carrier tape

tape carrier package definition

cassette tape carrying case

advanced carrier tape

daewon carrier tape

ic carrier tape

embossed carrier tape hs code

carrier tape roll hs code

argosy carrier tape

cpak carrier tape

carrier tape manufacturer in thailand